Retail Site Phase Separation Guidelines:

Due to the potential of substantial rainfall, retail sites which have never experienced phase separations may be more susceptible to water leaking into underground storage tanks as the water table rises. With that in mind, we would like to pass along some industry guidelines that may minimize the chance of a phase separation when reopening a station that has experienced heavy rain and/or flooding. Operator must confirm that product in all underground storage tanks is not contaminated with water and that no phase separation has occurred. Some suggested guidelines are listed below as well as more detailed industry guidelines in the attachments:

-

- Do not attempt to check product in tanks until fill well covers can be opened (no standing water on top)

- If spill basin contains water, it should be pumped out before removing cap on drop tube; water must not be released into the tank

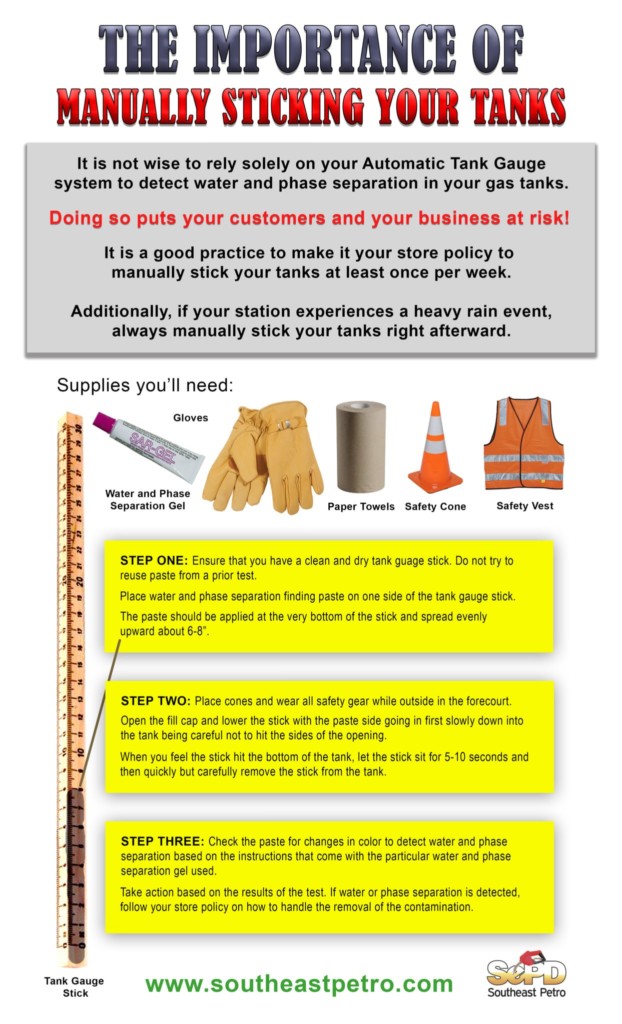

- Check tank bottoms for water or phase separation with a trusted water/phase separation detecting paste – do not rely on Veeder-Root tank gauging system

If no water is detected:

-

- Pump 15 gallons of each grade from dispenser that is closest to the tanks

- Dispenser flow rate must be >5 gpm and the fuel from dispenser should be clean and bright and a single phase

- If it’s determined that all is OK and a new delivery is made, driver should wait at least 15 minutes and then stick tank again (down the fill tube) with a trusted water/phase separation detecting paste

- If no water is found, sales can resume and station personnel should monitor dispenser flow rate to ensure it remains >5 gpm

If water is detected:

-

- Tank has likely experienced a phase separation

- “Bag” dispenser nozzles to prevent sale of contaminated product

- Procure a vacuum truck to remove entire volume of contaminated product (both the ethanol-water phase and the octane-deficient gasoline phase) and flush underground lines between tanks and dispensers

- Once the contaminated product has been removed, it should be delivered to a transmix tank or possibly sold to a fuel re-processor

- After a new delivery is made, driver should wait at least 15 minutes and then stick tank again (down the fill tube) with the water/phase separation paste

- If no water is found, sales can resume and station personnel should monitor dispenser flow rate to ensure it remains >5 gpm

See also Water & Phase Separation in Gasoline-Ethanol Blends (E10)